Whether you’re trying to keep power tool noise from disturbing your household, reduce vibration during mechanical work or prevent sound from carrying across property lines, managing noise is usually a post-purchase upgrade.

The good news is that adding effective noise control to a portable building doesn’t require tearing it apart. Many owners don’t even need to hire a contractor.

Two Types of Noise

Before choosing materials, it helps to understand what you’re trying to control:

- Airborne noise – Sound traveling through the air (music, saws, compressors)

- Structure-borne vibration – Sound created by vibration transferring through floors, walls and framing (engines, planers, lathes)

Most workshops deal with both, so upgrades should address absorption and vibration reduction together.

Interior Wall Panel Options for Sound Absorption

Bare interior walls reflect sound, amplifying noise inside the space and allowing it to escape more easily. Adding sound-absorbing surfaces is one of the most effective sound dampening upgrades.

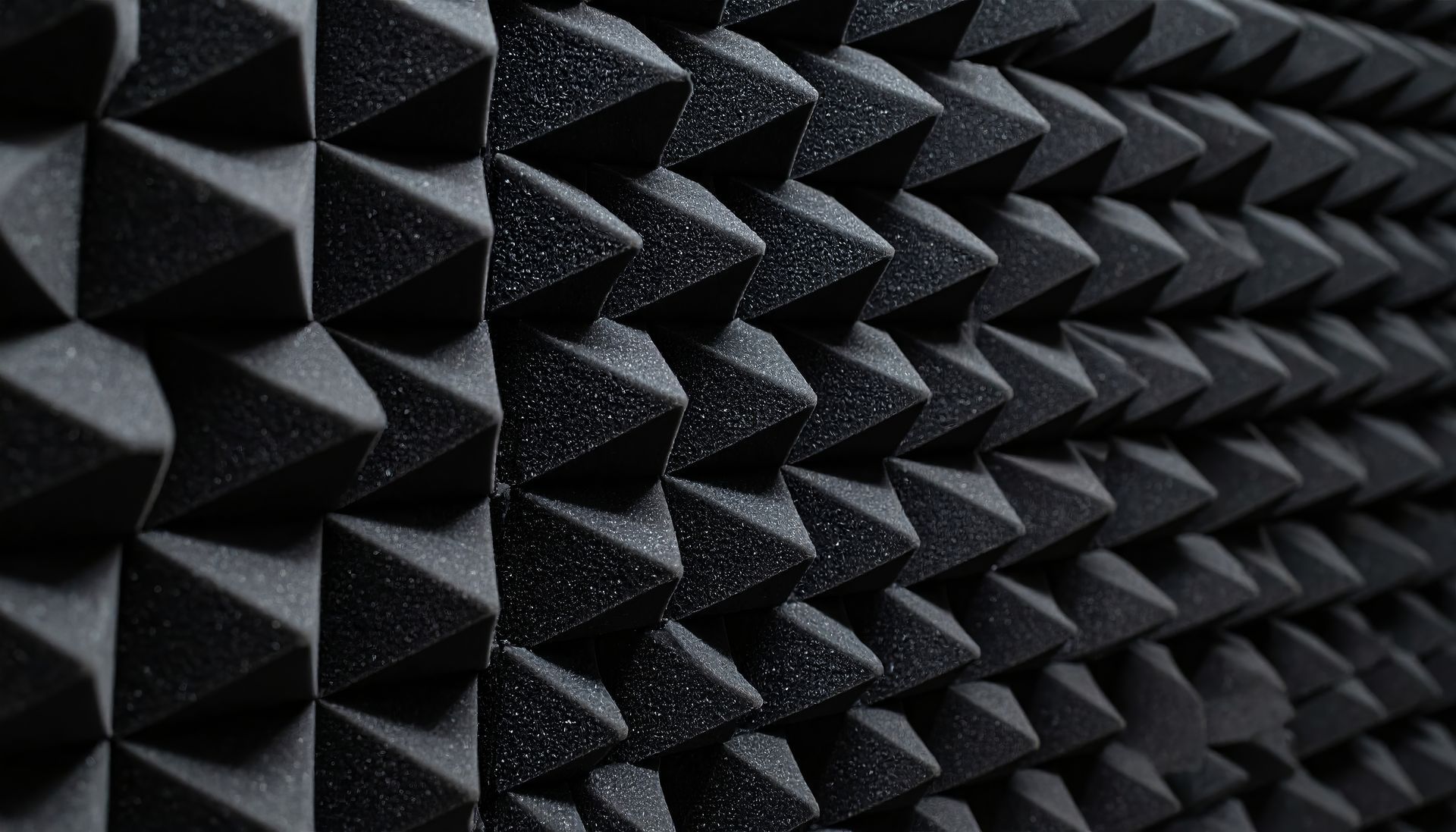

Acoustic Panels

Fabric-wrapped acoustic panels or foam panels reduce echo and high-frequency noise. These are especially helpful for music practice spaces or recording setups and can be mounted directly to interior walls without structural changes.

Mineral wool or Rigid Fiberglass Panels

These materials absorb a broader range of frequencies and perform better for loud tools and machinery. They can be installed behind decorative wall panels or left exposed, depending on aesthetics.

Plywood over Absorption Layers

For workshops that need durable walls, a layered approach works well: sound-absorbing insulation behind plywood wall panels. This balances noise control with durability for hanging tools or shelving.

Insulation Methods That Make a Difference

Insulation can also play a role in sound reduction.

Fiberglass Batt Insulation

When installed between wall studs and ceiling framing, batt insulation can significantly reduces airborne noise leaving the building.

Mineral Wool Insulation

Denser than fiberglass, mineral wool offers better sound absorption. It’s an excellent upgrade for woodworking shops and engine repair spaces where noise levels are higher.

Double-Layer Approach

If your portable building allows it, installing insulation plus an additional interior wall layer (such as drywall or plywood) improves sound dampening by adding mass, which helps block lower-frequency noise.

Ceiling Treatments Often Overlooked

Noise doesn’t just escape through walls; it travels upward.

- Insulating the ceiling cavity reduces sound transfer dramatically.

- Hanging acoustic baffles or panels from the ceiling helps control echo and vibration inside the space.

- For music practice rooms, ceiling treatments can make the room sound cleaner while also containing volume.

Even partial ceiling treatment can produce noticeable improvement.

Floor and Vibration Control Strategies

For workshops involving machinery, vibration is often the biggest issue.

Rubber floor mats or anti-vibration pads

Placing heavy equipment on rubber isolation mats reduces vibration transfer into the floor framing and ground.

Floating Work Platforms

For particularly loud tools, a small raised platform with rubber isolation underneath can help localize vibration.

Tool Placement Matters

Positioning noisy equipment away from exterior walls reduces how much sound escapes the building.

Door and Window Noise Leaks

Doors and windows are common weak points for sound leakage.

- Weatherstripping around doors helps seal gaps that allow sound to escape.

- Solid-core doors perform better than hollow ones for noise control.

- Window inserts or removable acrylic panels add a layer of sound blocking without replacing the window entirely.

Matching Noise Control to Your Use Case

- Woodworking: Focus on wall insulation, vibration pads and ceiling treatment.

- Small engine repair: Emphasize vibration isolation, dense insulation and sealed doors.

- Music practice: Prioritize acoustic panels, ceiling absorption and echo control.

Build the Right Foundation for Custom Upgrades

Bestway Portable Buildings offers custom portable buildings that can accommodate a wide range of post-purchase upgrades, from insulation improvements to interior customization. Call us at (850) 747-8974 to explore custom building options.